220V LPG Gas Cylinder Filling Machine 120Kg Capacity Gas Refilling Machine

Product Details:

| Place of Origin: | China |

| Brand Name: | Silk Road |

| Certification: | ATEX, CNEX, ISO9001 |

| Model Number: | S-TCS-YG-SV 120 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 Set |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Standard Carton Pack, Each Set Packed in 4 CTNS |

| Delivery Time: | 5-8 work days |

| Payment Terms: | L/C, T/T, Western Union |

| Supply Ability: | 1000000 Sets per month |

|

Detail Information |

|||

| Product Name: | LPG Refilling Scale Machine | Rated Power &Frequency: | 220V 50/60Hz |

|---|---|---|---|

| Division: | 50G | Capacity: | 2Kg-120Kg |

| Available Gas: | Liquid Gas | Accuracy: | III |

| Pressure: | 0~1.6Mpa | Anti Explosion Grade: | Ex Ib IICT4 Gb |

| Warranty: | 1 Year | Display: | LCD |

| Highlight: | 220V LPG Gas Cylinder Filling Machine,120Kg Capacity Gas Refilling Machine,1.6Mpa Gas Refilling Machine |

||

Product Description

The Filling Scale Machine is desinged for LPG Gas, Industrial Gas

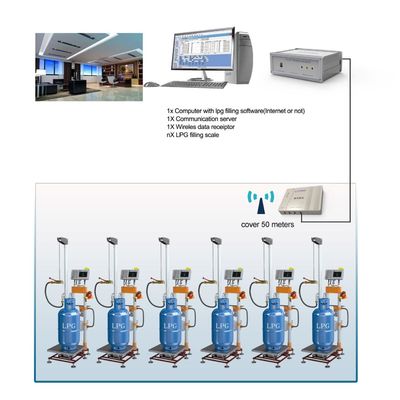

The Filling scales are used in semi-automatic and fully automatic filling processes within filling station. The filling scales with communication server, wireless base, cyinder tracking system and therefore have to meet high accuracy requirements.

| Performance parameters | |

| Module | S-TCS-YG-SV-120 |

| Accuracy | III |

| Min. & Max. weighing | 2KG-120KG |

| Certificates | CNEX, ATEX, ISO9001 |

| Div. | 50g |

| Operating pressure | 0~1.6Mpa |

| Suitable gas | LPG |

| Ex-proof | Ex ib IICT4 Gb |

| Power Supply | 220V |

| Rated Frequency | 50/60Hz |

Detailed spare parts of LPG filling scale, including:

1. Soldenoid valve,

2. power box,

3. hanging barrel,

4. tools,

5. display,

6. LPG pipes,

7. cable pipes,

8. support rod,

9. scale platform,

10. scanner and holder,

11. seals

![]()

Application in gas station:

![]()

- Quantitative filling,

- Automatic cut off, .

- Intrinsically safe explosion proof, safe and reliable

- One key setting, easy and convenient ,Friendly Keyboard, one key operation, large screen OLED display

The process of filling:

1.Place the cylinder on the empty scale platform and scan the cylinder barcode(press the scan key, and the laser line will be aligned with barcode symbol)

![]()

2. Open the valve(pressure handle) and start filling

![]()

3.After filling, the data will be transmitted into software system. Automatically cut off of the arrivak quantity and wirelss transmission of data. Through the software, the daily filling data and files can be statistically summarized.

4. The software system updates in real time and uploads the filling data to the network platform.