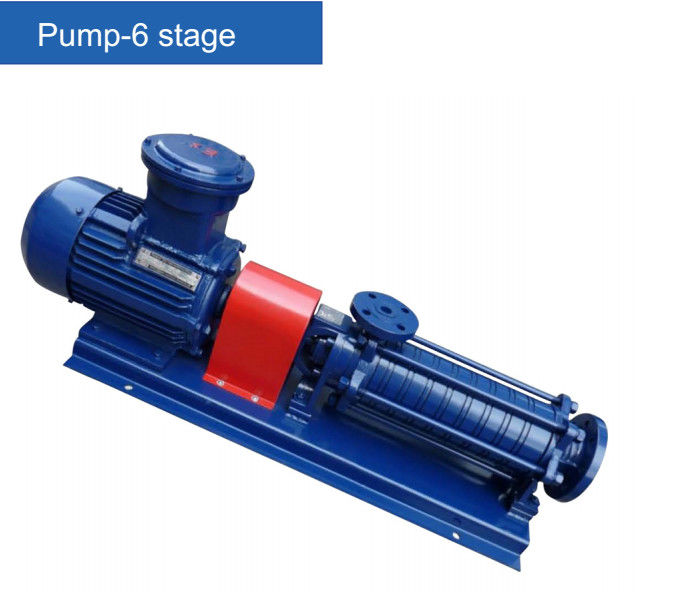

ISO9001 1170x400x490mm 6 Stage 308V 4KW LPG Gas Pump

Product Details:

| Place of Origin: | Changzhou, China |

| Certification: | CNEX, ATEX, ISO9001 |

| Model Number: | XKDZ-P30 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 Set |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Standard wooden case |

| Delivery Time: | 8-10 work days |

| Payment Terms: | T/T, L/C, Western Union |

| Supply Ability: | 100000sets per month |

|

Detail Information |

|||

| Item Name: | Pump-6 Stage | Direction Of Rotation: | Anti-Clockwise Facing The End Of Pump Drive Shaft |

|---|---|---|---|

| Max. Pressure: | 40 Bars At 120℃ | Speed: | 1450rpm |

| Power: | 380V, 50Hz,4KW | Ambient Temperature: | 20℃~+60℃ |

| Number Of Stage: | 6 | Connection Flange: | DIN 2501, PN40 |

| Bearing: | Sleeve Bearing At End Pump End, Ball Bearing At The Drive End | Package: | 1pc Wooden Case |

| N.W.: | 120Kgs | G.W.: | 144Kgs |

| Meas.: | 1170x400x490mm | ||

| Highlight: | 4KW LPG Gas Pump,308V LPG Gas Pump,4KW lpg gas transfer pump |

||

Product Description

A liquefied petroleum pump in a LPG service station that draws LPG from underground storage tanks...

the specification for checking:

| Performance parameters | |

| Module | Pump-6 stage |

| Power | 380V, 50Hz,4KW |

| Max. Pressure | 40 bars at 120℃ |

| Bearing | Sleeve bearing at end pump end, ball bearing at the drive end |

| Ambient Temperature | 20℃~+60℃ |

| Connection flange | DIN 2501, PN40 |

| N.W. | 120Kgs |

| Meas. | 1170x400x490mm |

| Package | 1pc wooden case |

![]()

LPG transfer pump used for refilling from large LPG cylinder to small LPG cylinder.

![]()

![]()

![]()

1. Use the LPG pump inlet gun to connect with the gas cylinder, open the cylinder angle valve, inverted cylinder. Such as large cylinders for the liquid phase, gas phase two mouth, then the liquid phase, the cylinder does not stand upside down. (The large cylinder is higher than the pump export is best guide) See if the pointer of the pressure gauge is turning. Normal pressure is about 2 kg.

2 .Open the pump outlet gun switch, when you first use of the pump, You need to exhaust the air inside the pump, and then connect the empty cylinder, open all the switches.

3. Test, Hand wheel, Check whether there is debris in the LPG pump, Then turn on the power switch, Look at the pump forward and reverse.

4. Tarking, The cylinder filled after power off, stop the operation of the pump, and then close the valve.

Some pics of the LPG gas pump for reviewing:

![]()